In the complex world of manufacturing, unexpected delays are not just a nuisance; they are a direct threat to your lead times, customer satisfaction, and bottom line. Juggling supplier delays, machine breakdowns, and resource shortages can feel like a constant battle. What if you could move from reactive firefighting to proactive control? This is where Smart Buffering, a powerful methodology built on the Theory of Constraints (TOC), transforms your operations by providing a clear, visual system to manage and protect your production flow.

Smart Buffering isn't about adding excessive padding to every task. It's a strategic approach to absorb variability and uncertainty, ensuring that minor disruptions don't derail your entire schedule. By focusing on protecting the overall flow rather than individual tasks, you can achieve greater efficiency, predictability, and consistent on-time performance.

Understanding the Core: What is a Buffer?

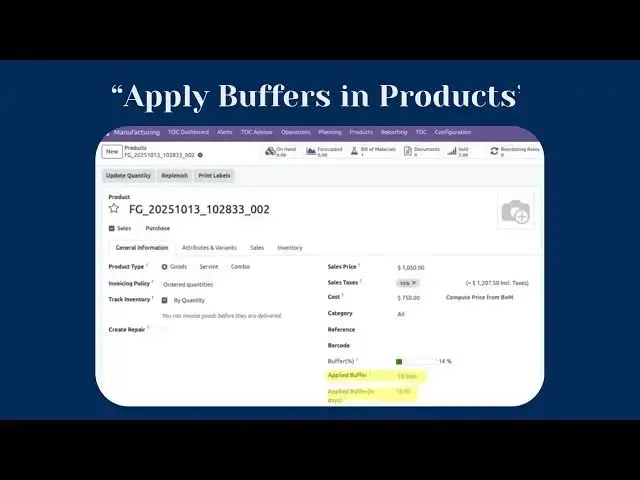

At its heart, a buffer is simply an extra amount of time or quantity strategically added to a process to absorb unexpected delays. Think of it as a safety cushion for your workflow. For example, if an order typically takes ten days to produce, you might add a five-day buffer, resulting in a 15-day commitment date. This extra time isn't meant to be wasted; it's there to protect the final delivery date from the inevitable hiccups that occur in any production environment.

The key principle, derived from the Theory of Constraints, is that the buffer's purpose is to protect the entire system's throughput, not just a single step. By monitoring the consumption of this buffer, you gain a powerful leading indicator of your operational health.

In short, a buffer protects the flow, not the task.

The Power of Visual Management: A Color-Coded System

One of the most effective features of a Smart Buffering system is its intuitive, visual dashboard. Instead of digging through complex reports to find problems, your team can instantly gauge the status of every order with a simple color-coded system. This allows everyone, from the shop floor to the management office, to prioritize their attention and resources where they are needed most.

Each order is dynamically tracked, and its buffer consumption is represented by a specific color, indicating its current flow status:

- Green (Safe Zone): The order is progressing smoothly, with most of its buffer intact. This is the healthy state, requiring no special intervention.

- Yellow (Warning Zone): The order has consumed a significant portion of its buffer. It's approaching a potential constraint and requires monitoring to prevent further delays.

- Red (Critical Zone): The buffer is nearly depleted. This order requires immediate attention and proactive measures to avoid a late delivery.

- Black (Over-Consumed): The buffer has been fully consumed, and the order is now officially delayed. The focus shifts to damage control and communicating with the customer.

This simple yet powerful visual cue empowers your team to focus on what needs action first, fostering a culture of proactive problem-solving and ensuring better control across all operations.

An Integrated System: From Supplier to Customer

A truly effective buffer management system must be integrated across the entire supply chain. Delays don't happen in a vacuum; a late component from a supplier directly impacts the manufacturing schedule, which in turn affects the customer delivery date. Our module provides this holistic view by tracking buffer consumption at three hierarchical levels:

1. Purchase Orders (PO) - Tracking Supplier Delays

The journey begins with procurement. The system tracks supplier delivery delays using calendar-aware calculations that only count actual working days. If a material delivery is late, the delay in days is recorded. This doesn't consume a buffer percentage directly, but it provides crucial data that feeds into the next stage.

2. Manufacturing Orders (MO) - Monitoring Production Consumption

This is where the buffer is actively consumed. The system calculates a buffer percentage based on the cumulative delays. It's intelligent enough to only start counting delays after all necessary components are available, preventing the manufacturing team from being penalized for supplier issues. Delays from machine downtime or work center bottlenecks are tracked here, giving a clear picture of internal production efficiency.

3. Sales Orders (SO) - Assessing Customer Impact

Finally, the sales order aggregates all buffer consumption from the associated manufacturing and purchase orders. It provides a single, comprehensive percentage that reflects the total impact on the customer's commitment date. Whether your products are Make-to-Order (MTO) or Make-to-Stock (MTS), the system accurately traces the flow to give you a true health score for each customer order.

From Visibility to Proactive Action

Gaining visibility is only half the battle. The true power of Smart Buffering lies in enabling proactive management. When an order's buffer status turns red, it’s not a failure; it’s a signal to act. The system empowers managers to make informed decisions quickly to get things back on track.

This system transforms visibility into action, helping teams recover from delays faster, prevent bottlenecks, and maintain smooth, on-time delivery across all orders.

When a critical buffer level is reached, managers can:

- Extend Completion Time: Realign planning and communicate a new, realistic timeline to stakeholders.

- Reallocate Resources: Shift high-performing teams or equipment to the critical order to increase efficiency.

- Adjust Working Hours: Authorize overtime or add extra shifts to catch up on lost time.

- Flag Products: Temporarily mark a product as unavailable for new orders if production is severely halted, preventing further overcommitment.

By implementing a Smart Buffering system, you’re not just tracking delays—you’re building a resilient, responsive, and highly efficient manufacturing operation. You can finally move beyond constant firefighting and start steering your production with confidence and control, achieving the on-time performance that builds customer trust and drives business growth.

Live DEMO: https://youtu.be/RktjhtPsB9s